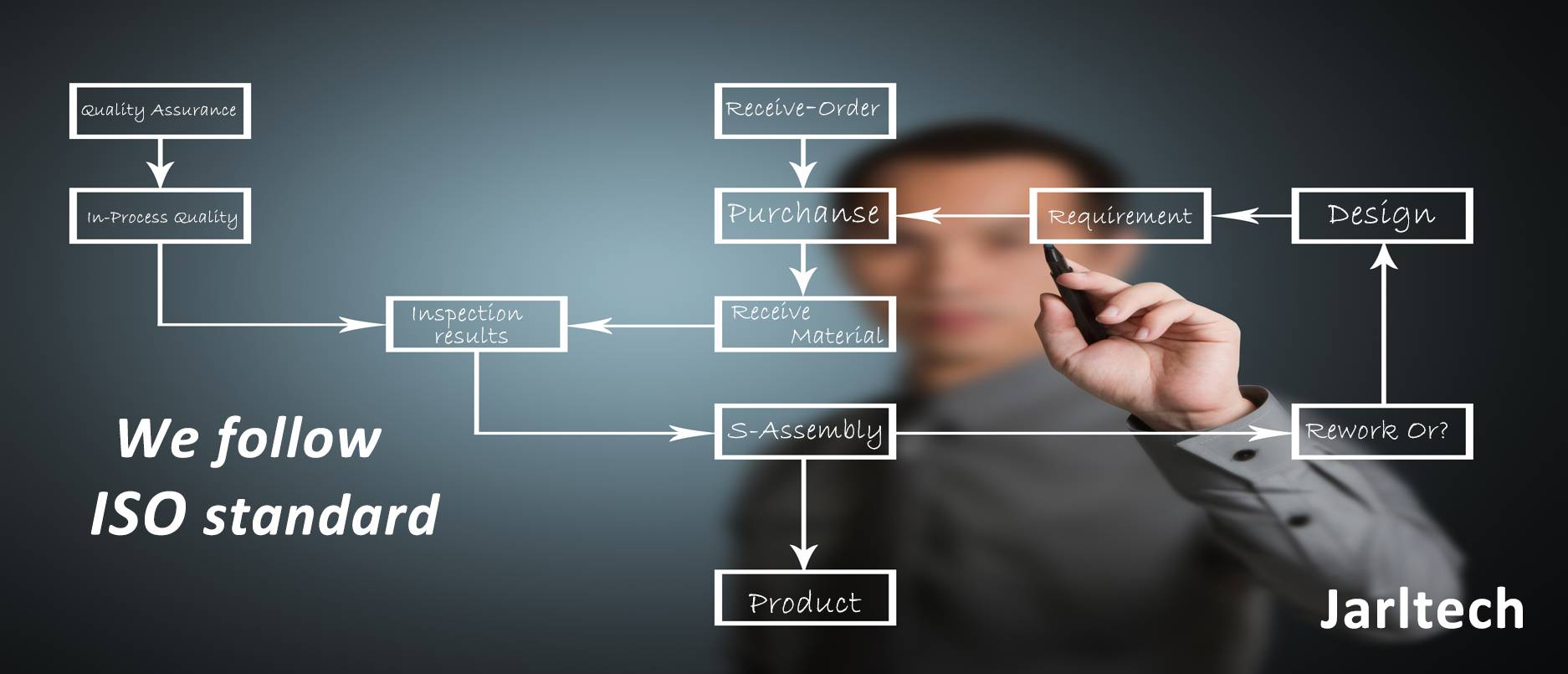

Production Procedures

ISO Standards Compliance

Production Procedures: A manufacturing process is a dynamic system with evolving structures, and its behavior is different from the individual components that make up the system.

A guide to the manufacturing process

When a manufacturing company begins to produce a new material, it must select the appropriate manufacturing process based on its facilities, personnel, and information systems. Each process has its strengths, such as handling large production volumes or small, customized orders. Key considerations in selecting a process include the required production volumes, the specific requirements of the product, and the company's experience with similar products.

It is important to consider the key manufacturing processes available, including production line, continuous flow, custom manufacturing, and fixed-position manufacturing.

Production Line

A production line is the conventional approach often linked with manufacturing. In this method, products are moved sequentially from one workstation to another, with specific operations carried out at each stop. The item may travel on a conveyor belt, be manually moved by workers, or transported by forklift. Typical steps along the production line might include assembly, painting, drying, testing, and packaging. In some cases, components can be temporarily removed from the line and stored as semi-finished goods before being reintroduced later in the process.

The production line manufacturing process is ideally suited to the high-volume production of a single product or product group. For example, a production line could be used to manufacture a range of vacuum cleaner models, with variations limited to the color of the plastic components and the included attachments.

The production line manufacturing process has inherent limitations. The design of the production line, which is optimized for the manufacture of a single product or similar products, limits its versatility. For instance, a production line set up for vacuums cannot be used for kitchen mops. Furthermore, the high initial setup costs and the necessity for substantial production volumes make it a considerable capital investment.

Continuous Flow

The continuous flow manufacturing process is similar to a production line in that it involves moving products through a series of stages without interruption or storage. However, there are key differences. This process is well-suited to materials such as chemicals, pharmaceuticals, and plastics that require uninterrupted production. One disadvantage of continuous flow is its lack of flexibility. Adapting it to produce different materials requires significant modifications, which are costly.

Custom Manufacturing

For companies that produce a variety of products tailored to specific customer requirements, custom manufacturing is an optimal solution. Such facilities employ a skilled workforce and utilise a range of equipment suited to the production and modification of diverse items. Typically equipped with dedicated areas for welding, lathe operations, paint spraying, and packaging, custom manufacturing is well-suited for delivering personalized products. However, it is not the optimal choice for high-volume production.

Fixed Position Manufacturing

Fixed position manufacturing is a distinctive process that maintains the product in a stationary position throughout production. This method is well-suited to large-scale projects, such as aircraft or ship construction, where relocating the product is impractical. Additionally, this method is employed for the on-site assembly of products, such as conveyor systems, where the assembly occurs at the final destination.

Electronic Manufacturing Services (EMS)

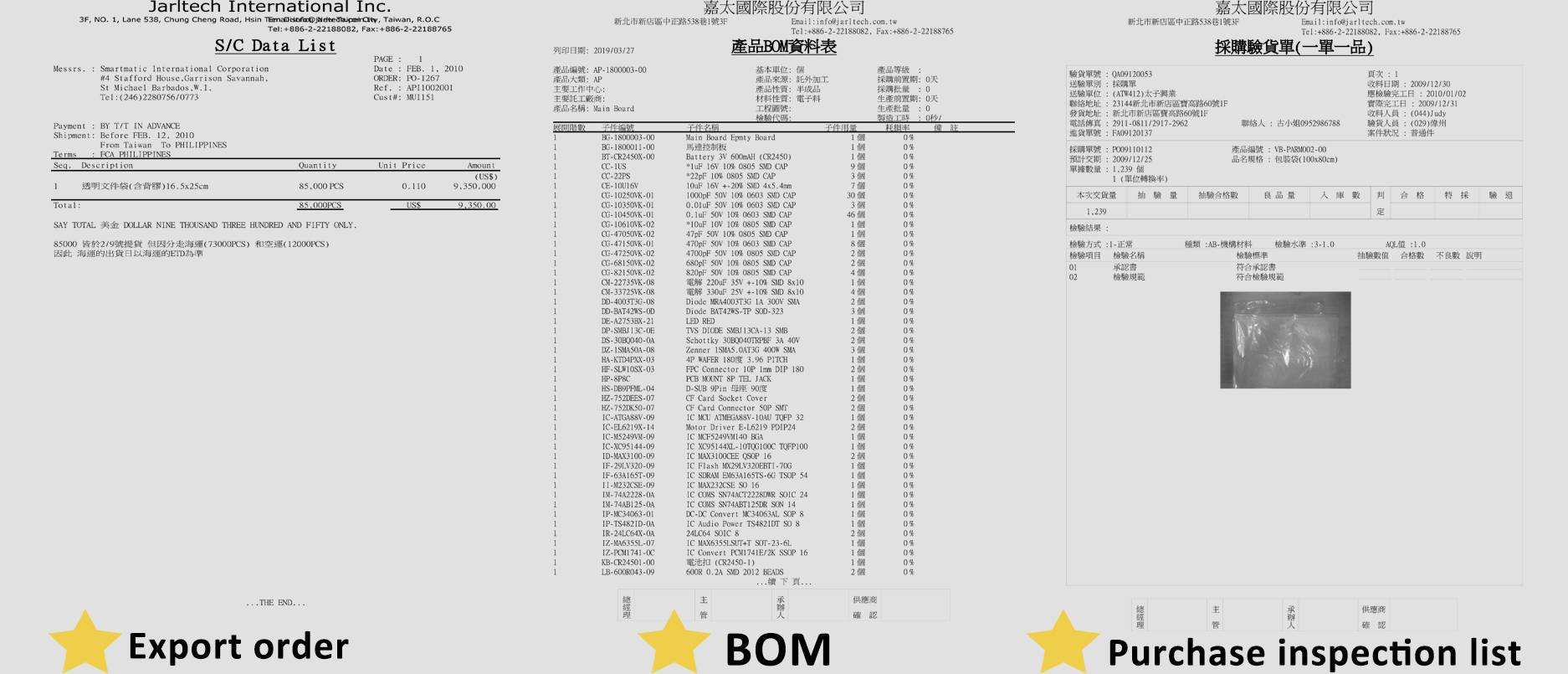

Jarltech offers comprehensive Electronic Manufacturing Services (EMS), including the design, assembly, production and testing of electronic components and printed circuit board (PCB) assemblies for original equipment manufacturers. We can be involved in different stages of the manufacturing process: some customers only provide a design file and we take care of component sourcing, assembly and testing. Alternatively, we specialize in assembly and can assist with product design. Jarltech also offers additional services such as PCB etching, either in-house or through our trusted partners.

.jpg?v=526880a6)