Stages of Electronics Development

Electronics Design and Development Phases

The electronics development process includes

Development process

For many companies, effectively managing the electronics design process is of the utmost importance. It is essential that the process be structured in a way that allows for orderly control while still fostering the creativity of the designers.

Many companies use standard methods to manage the design process, while others are increasingly adopting Web-based approaches. Regardless of the method used to present and share information, certain common activities are consistently part of the overall electronics development process.

The electronics design process can be tailored to meet specific needs, with the goal of supporting rather than disrupting the overall workflow. While some activities may seem redundant, they are often necessary to ensure that the final product is both repeatable and maintainable over time.

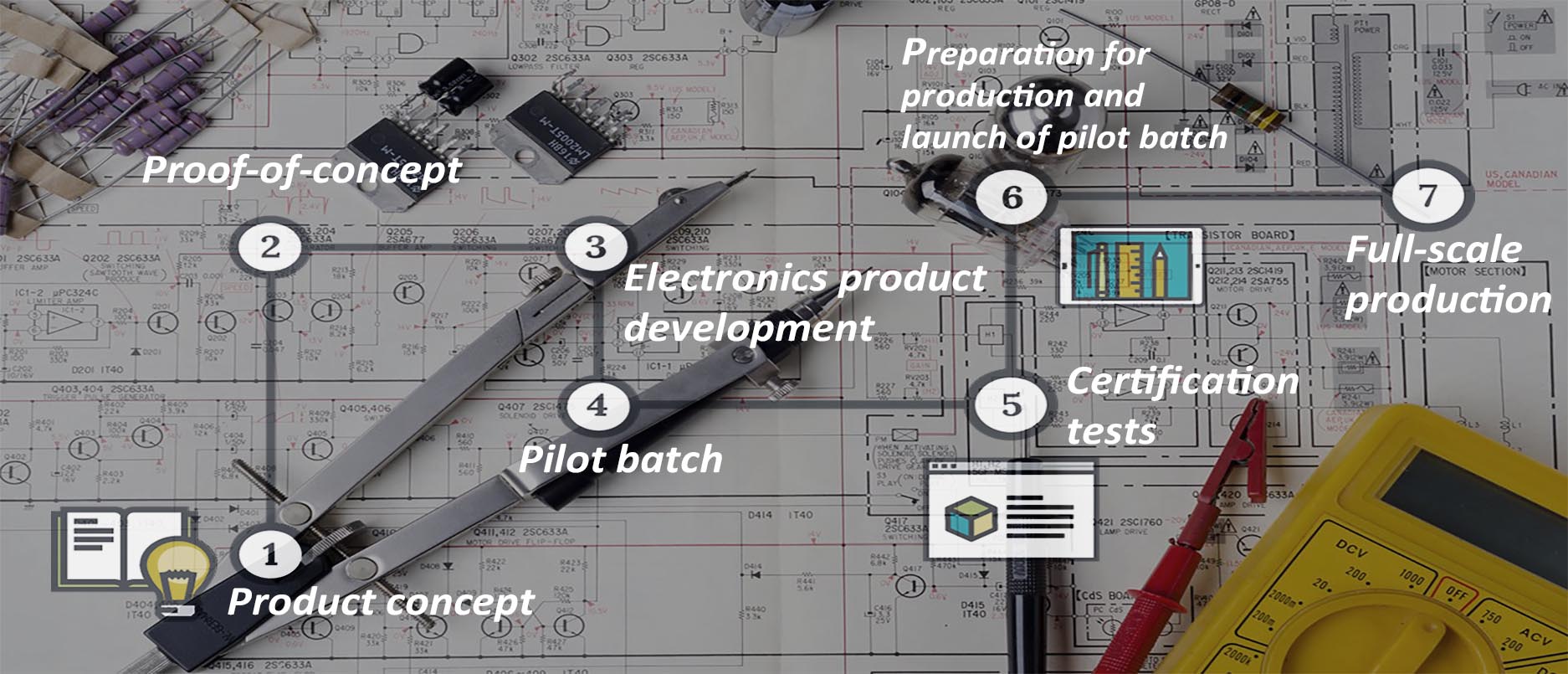

Our company has established a comprehensive classification for the main development stages of new electronic products. This framework encompasses seven critical stages essential for designing any electronics product. By following this structured approach, we effectively minimize risks and prevent them from escalating into the final stage of full-scale production.

Keep in mind that each stage can include multiple iterations. This iterative approach is especially useful for developing complex products, such as designing software/hardware platforms that form the basis of product lines.

The electronic product design process includes the following key stages

1. Concept Development

In the first phase of our electronic design services, we transform ideas into a product with commercial potential. Our experts select a business model to optimize the market success of the electronic device being developed.

Next, Jarltech's technical team and industry experts develop a detailed product specification and concept design. The specification outlines all product requirements, while the concept design provides a comprehensive description of the functional features and benefits.

Meanwhile, business analysts develop a business plan based on the selected business model and expert input. This phase may also include various types of product research, such as market or investment analysis. The result is a comprehensive documentation package detailing the product concept.

2. Concept validation

The second stage of the process entails the creation of a preliminary project draft, the establishment of requirements and specifications, and the analysis of potential applications for the product.

The next step is to negotiate prices with the companies that manufacture the required components. Once the manufacturers have been selected, a non-disclosure agreement (NDA) is signed and, if necessary, additional technical data is obtained. We then select the base components and calculate the preliminary cost of the product, which is known as the bill of materials (BOM). These preliminary calculations take into account the cost of manufacturing different batch sizes.

Our specialists then review the device implementation. At this stage, a prototype is assembled and tested. We purchase an evaluation kit for the selected target platform to support development and assembly. Our engineers evaluate the selected hardware and software solutions, identifying potential weaknesses in terms of technical feasibility, platform performance, and other key characteristics.

At the conclusion of this phase, we ascertain whether the selected platform and engineering solutions are the most suitable. Additionally, we frequently create a basic prototype for further assessment.

3. Electronics Product Development

The third stage is to develop a complete set of design and project documentation for the new device. This includes listing the necessary components, designing the PCB (printed circuit board), and creating a Bill of Materials (BOM) with detailed component information. We also obtain accurate pricing from suppliers.

The next stage of the process is the design of the HMI (human-machine interface) and the establishment of the control and display units by our engineering team. Additionally, they develop the interface, design control concepts, and create the functions tree. At the same time, we create a solid model and mechanical design for the device case, based on the initial sketch and HMI. The final stage is the PCB layout, which is completed in accordance with the specified form factor.

Following the definition of the software architecture in the preceding phase, we proceed with the implementation and refinement of the software. Our team performs comprehensive testing to guarantee that the software functions correctly and integrates seamlessly with the hardware. Furthermore, we develop tests to verify the performance of both the hardware and the software. By the conclusion of this phase, we will have produced a comprehensive set of design documentation and prepared for the pilot batch manufacturing.

4. Initial Test Batch

The fourth stage is concerned with the production of a pilot batch, the purpose of which is to verify the operability of the device. This phase allows for any design errors to be identified and rectified, thereby ensuring that the product functions as intended. In addition, customers utilise these pilot samples for product promotion to potential buyers or investors and for certification testing.

At this stage, Jarltech's specialists procure and assemble the necessary components, initiate PCB production and confirm the ease of assembly. We then order enclosures that resemble the final version. After PCB assembly, the first bring-up is performed. The operating system and boot loader are then ported, and high-level software, system integration and drivers are developed. Finally, Jarltech specialists complete the assembly of the device components and perform thorough integration tests.

Once the testing results are obtained and the operational tests have been conducted, we will be able to refine the product's functional requirements and update the design documentation as needed. The majority of software modifications can be addressed in subsequent stages, as they generally do not require hardware changes.

Some customers want to repeat one or more iterations of electronics development, which can lead to changes in design, schematics, and PCBs. This situation is more likely to occur if stages 1 ('product concept') or 2 ('proof of concept') have been skipped. Upon completion of this stage, a functional pilot batch will be prepared for integration testing. Following the conclusion of testing, the design documentation can be updated as necessary.

5. Certification Testing

Based on our experience, it is inadvisable to skip preliminary certification tests, as this significantly increases the risk of material losses later on. At this stage, we determine the device classification, assess the need for preliminary certification trials, and develop a testing schedule. Once test results are available, our specialists document the findings and update the design documentation as needed.

Upon completion of the fifth stage, we will receive a decision from the relevant organization regarding the implementation of preliminary certification tests and the results of those tests.

6. Production preparation and pilot batch launch

The objective of the pilot batch launch is to prepare the product for full-scale manufacturing and test the production process. This stage enables the identification of defects that may not be apparent in a small batch, while also allowing for minor adjustments to the PCB, case design, or schematics.

Jarltech's specialists then complete the optimization of the BOM, prepare the final documentation package, and work with our engineering technologists to develop assembly diagrams for the specific products. In addition, detailed logistics plans are created and potential bottlenecks, risks and weaknesses in large-scale production are assessed.

Meanwhile, tools for POST testing and post-production testing are developed if additional test coverage is required. The outcome of the sixth stage is a produced pilot batch and the documentation required to initiate full-scale production of the device.

7. Full-scale production

The objective of this final stage is to facilitate the full-scale industrial manufacturing of the product, ensuring its readiness for sale to end users. During this phase, our engineering team can provide support for mass production in the following ways:

•Technology Process Management

•Product quality control

•Prompt response to component replacements (e.g., when a component is unavailable)

•Identify causes of production defects (e.g., process variation or poor-quality components)

•Expand test coverage and improve procedures for addressing identified bottlenecks

•Optimize the production process to reduce costs

The result of this stage is the quality assurance of the production process and the delivery of the manufactured product batch to the customer.

Stages of Electronics Development | High-Quality Self-Service Kiosk Solutions | Jarltech

Located in Taiwan since 1987, Jarltech International Inc. has been a developer and manufacturer of POS and Kiosk systems for restaurants, retail stores and supermarkets. Their main software and hardware products include, Stages of Electronics Development, small business POS systems, self-service kiosks, smart card readers, Bluetooth thermal printers, embedded motherboards and all-in-one panel PCs, focusing on providing interactive kiosk solutions.

Leverage Jarltech’s 30+ years of expertise in developing innovative POS and Kiosk systems tailored for diverse business needs in restaurants, retail stores, and supermarkets. Our specialized solutions, encompassing IPC, Touch Monitor, Thermal Printer, and Smart Card Reader, are designed to elevate your business operations, ensuring seamless transactions and enhanced customer experiences.

Jarltech has been offering customers global B2B solutions with Jarltech’s POS and Kiosk Systems since 1987, both with advanced technology and 37 years of experience, Jarltech ensures each customer's demands are met.